-

SYH-50 Three-Dimensional Mixer

Working Principle: The mixing barrel is suspended at the end of the main and driven axles through two Y-type universal joints. The two universal joints intersect and perpendicular to each other in space. When the drive shaft is dragged and rotated, the cardan envoy barrel moves repeatedly in space, such as translation, rotation and roll. Material in the cylinder is followed by three-dimensional compound movement in the axial, radial and circumferential directions. Many kinds of materials in t... -

6 Barrel Powder Mixer

1. Equipped with six 10L / 2-3KG mixing barrels at a time, and rotate at the same time as the revolution, 30 revolutions per minute and 40 rotation per minute. 2. Steering and speed can be adjusted according to technical requirements, with 1.5kw 2P reduction motor. 3. Configure the emergency stop switch, set the process timer. 4. Configure 10 plastic mixing buckets with a capacity of 10L. 5. 380V 50Hz 3P. -

PTFE Sintering Furnace

Product Description: PTFE Industrial Nitrogen Sintering Furnace.Capable of paperless recording and group-unrestricted programming. Its sintering records can last one year. The multiple sintering furnaces can be operated at the same time and the remote control is available. PTFE Sintering Furnace Features: Sunkoo sintering Furnace deliver tight temperature control and temperature uniformity throughout the heated chamber providing an efficient and consistent sintering process from cycle to cyc... -

The v-100 PTFE Powder mixer

Equipment technical parameters: 1,Mixing barrel total volume of 100L, Material handling capacity: 40-50L 2, Equipment main motor power 1.5 kw. 3,Mixing time Digital setting 0-99 minutes, timing shutdown. 4,power supply: 380V/220V/50Hz. Part 1 : Equipment OverviewEquipment name: V-type mixerEquipment model:V-100Equipment number:one setEquipment usage: For the mixture of powder Basic requirements: 1,Each 40-50L material / batch mixing, and do not bring any impurities in the process of mixing... -

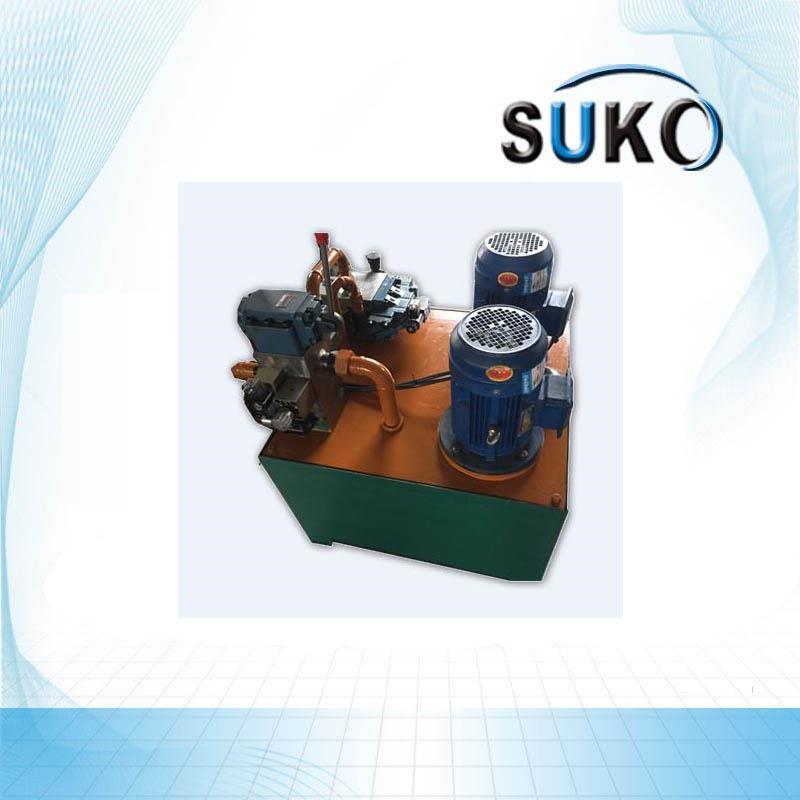

Automatic PTFE Hydraulic Press Moulding Machine

1. Characteristics of PTFE Molding Machine Molding Machines are divided into manual, semi-automatic and fully automatic molding machines. Through continuous improvement of the molding press technology, the equipment is more intelligent, more stable, and more efficient. The intelligent automatic type is controlled by PLC system, to set the pressure, range, speed, quantity, and dwell time, and the operation is simple. With diverse design, the equipment can meet the different needs of users, an... -

Plastic PTFE Semi-automatic Molding Machine

Since PTFE will not flow above its melting point, it cannot be injection molded and requires special processing techniques. Molded PTFE is processed by first compression molding the powder into preforms, and then sintering the preforms in a process analogous to sintered metal processing. This process creates geometric shapes that can then be machined, fused, and/or welded. Product Description for Automatic Molding: Automatic molding, a semi-automated form of compression molding, is the proces...

Hello, come to consult our products !